BEASA, in view of the execution of works for the Pascua Lama project to be carried out by sanjuaninos suppliers, DINSA hired to conduct training and comprehensive training of these workshops.

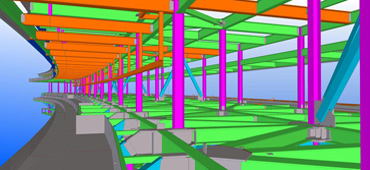

DINSA as the current supplier of the project and who was responsible for the construction of the mill building, agreed to this request for BEASA and is currently developing this course counting on the assistance of 9 workshops selected for the implementation of the 160 ton support structures plumbing project and other works.

MiningPress consulted about it Diego Villarroel, Sales Company and Managing DINSA building Milling Project, says.

"Fluor-Techint Beasa and asked us to give training to sanjuaninos suppliers, because they understand the need to incorporate the project, but wanted trasmitiéramos our knowledge of processes and our experience, we agreed willingly. For this we brought those responsible for each area of our company and outside contractors to perform not only a theoretical exposure, but a practice at each workshop as well, on a subsequent visit, be understanding and application of knowledge provided. They are part of this, our Quality Manager, Ing Purificato Silvia, who is in charge of this project, Mr. Eladio Meireles (Nace III) Company Pintec, Mr. Raul Vesco, Factory Manager, Mr George Semeniuk company JLS, Mr Lucas Fiolone Industrial Maintenance company. "

He adds: "I was in charge of giving the start to this workshop and commented, that our experience in the project was to work on a par with Fluor -Techint in absolute confidence, and that relationship is based on the certainty of our promises, as they always have needs that depend on our supply, and if we failed them would damage exponential in the project. That is the true capital providers must manage and take care of them and so I stressed the importance of developing production schedules according to the possibilities of each and to the needs of the provision. "

"The kind of supply you. Develop, referring to the suppliers of the province, are in constant demand in the years of operation of the mine no great works, such supplies are emerging daily, or no a potential 25 years ahead, we must not waste it. "

A day to start the last part of the course Purificato Ing comments:

"This was a great recognition for the performance of productivity, quality and customer service achieved by DINSA, while a new challenge.

"In a short time we had to train and train sanjuaninos providers to understand the needs, expectations and requirements of a World Class Customer as is BEASA and Fluor Techint."

"I Developed integrally training and training based on a multidisciplinary team of highly qualified and expectations of our client, and thankfully the results were less than four days."

"Motivation levels reached at the end of the first day of training and training results beat the odds definitely the interaction was of mutual convenience."

Surely this is a contribution to the workshops who wish to participate in mining, approaching them knowledge and firsthand experience, and recognition of the efforts of all those involved.